The necessity of installing ESD access control system in electronic production workshop

![]() July 16, 2021

July 16, 2021

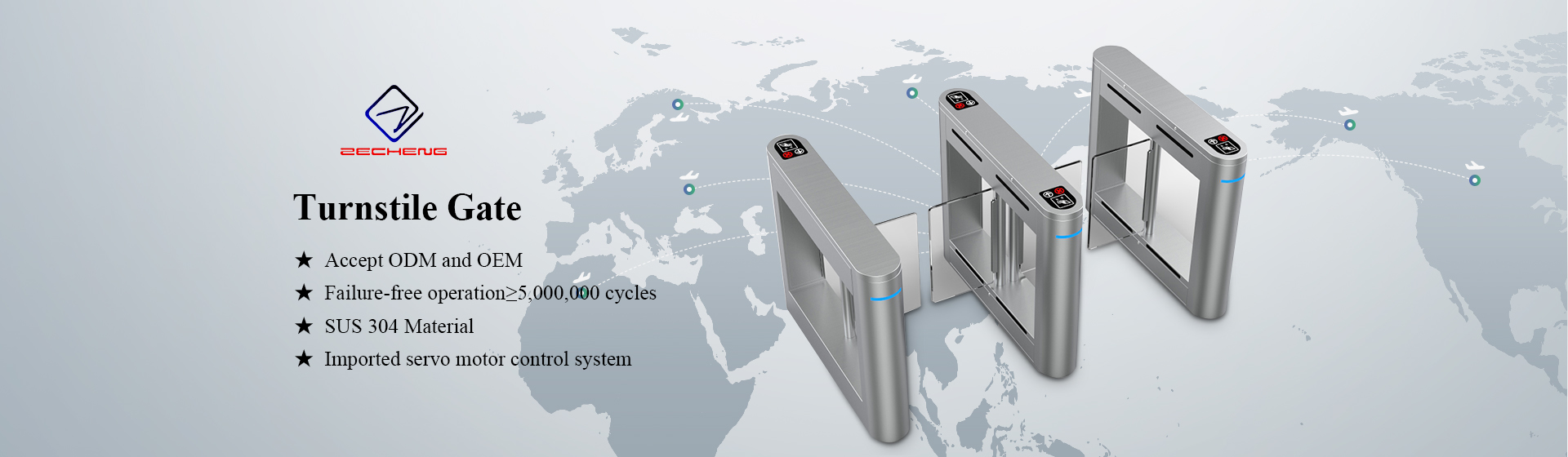

At present, most electronic companies still use the human body comprehensive static tester. The fatal flaw of the tester: it relies on the self-consciousness of the workshop staff and the supervision and inspection of the administrator. In order to protect the static electricity more effectively, it is necessary to control the source of static electricity. To this end, an anti-static access control system is introduced for key areas. The access control system can detect whether the anti-static measures or equipment of each worker who enters the anti-static area is qualified. System function modules include: identity and authority confirmation, anti-static wrist strap and anti-static shoes detection, level control board, etc.

To further ensure the effectiveness of anti-static access control, for some manufacturing companies that require cleanliness of the working environment, the access control system can be linked with the air shower dust removal system leading to the work area, that is, the access control signal is integrated into the air shower door control system. This type of mode can ensure that the anti-static equipment is qualified and effective from the first pass into the work area.

Although the discharge voltage of ESD may be as high as several thousand volts, due to the limited amount of electricity, the discharge time is completed in an instant, so the damage caused is often the breakdown of the semiconductor dielectric layer and the semi-melting of the metal layer. The damage is difficult to be directly found in the later detection. , But the damage caused often makes the product appear in the hands of the end user, and this is the most unacceptable to us; secondly, the economic loss caused by ESD will be amplified step by step along the industry chain, and ESD directly damages the components, but With the assembly and integration of products, the final impact will be on products and systems, and losses will be amplified step by step. If upstream companies incur claims from downstream customers, they will far exceed the value of their products. Finally, and most importantly, ESD The control to solve is not a pure technical problem but a systematic project. It involves all aspects of work such as material technology, quality management, reliability analysis, staff training, inspection and audit, etc. The level of ESD control actually reflects The level of its reliability and quality management, therefore, it has become one of the core conditions that EMS customers pay attention to when choosing a supplier.

The above is the The necessity of installing ESD access control system in electronic production workshop we have listed for you. You can submit the following form to obtain more industry information we provide for you.

You can visit our website or contact us, and we will provide the latest consultation and solutions

Send Inquiry

Most Popular

lastest New

Send Inquiry